Imikhiqizo

Izikulufa ze-Chipless Chipboard ze-Stainless

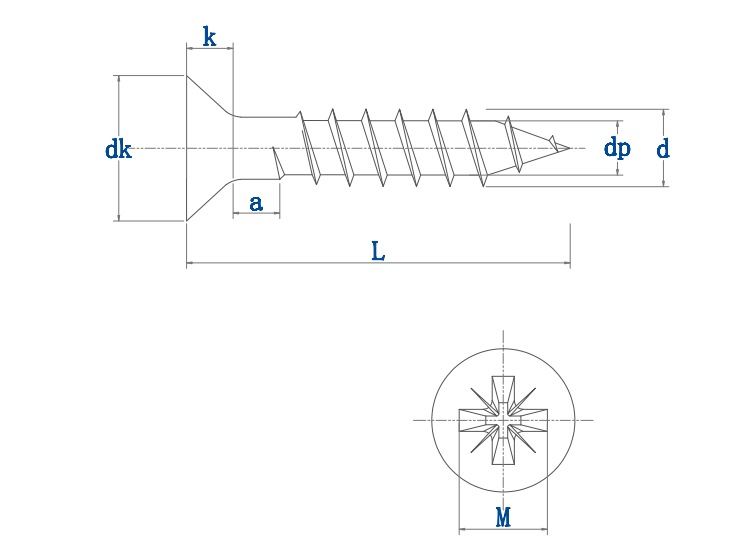

Ukuchazwa Komkhiqizo

| Igama lomkhiqizo | Izikulufa ze-Chipless Chipboard ze-Stainless |

| Into uqobo lwayo | Kwenziwe ngensimbi engama-304 engagqwali, lezi zikulungisa zinokumelana kahle kwamakhemikhali futhi kungaba yinkimbinkimbi kazibuthe. Baziwa nangensimbi engenacala. |

| Uhlobo lwekhanda | Ikhanda le-CounterSunk |

| Uhlobo lweDrayivu | Cross recess |

| Ubude | Kukalwa ekhanda |

| Isicelo | Izikulufo zeChipboard zilungele imisebenzi yokwakha ekhanyayo, njengokufaka amaphaneli, ukugoqa odongeni, nokunye okulungiselelwe lapho kutholakala khona amandla abo okuhlinzeka ngenqaba, kusetshenziswa kabanzi emhlanganweni we-chipboard kanye ne-MDF (Ifenisha ye-fiberboard ephakathi nendawo). |

| -Vamile | Izikulufo ezihlangabezana ne-ASME noma i-DIN 7505 (a) ngamazinga wobukhulu. |

Zuza ngezikulufo ze-Counterning Countersenk Chipboard

1. Ukumelana nokugqwala: Kwenziwe ngensimbi engenasici, lezi zikulungisa zimelana kakhulu nokugqwala nokugqwala, okwenza zilungele ukusetshenziswa ezindaweni ezivezwe umswakama noma izimo ezinzima.

2. Ukudluliswa kwesikhalo esihle: Idizayini ye-Countersunk ivumela inhloko yesikulufa ukuze ilingane ne-flush noma ngaphansi kobuso bezinkuni, inikeze isiphetho esihlanzekile futhi esibushelelezi. Lokhu kubaluleke kakhulu ezindaweni ezibonakalayo lapho ukubukeka okuhle kufiswa khona.

3. Amandla nokuqina: Insimbi engenasici ihlinzeka ngamandla amahle nokuqina, ukuqinisekisa ukuthi izikulufo zibambe kahle ngokuhamba kwesikhathi ngaphandle kwesikhathi ngaphandle kokuphola noma ukwephula ngaphansi kwengcindezi.

4. Ukuhambisana ne-chipboard: Lezi zikulufo zenzelwe ngokukhethekile ukusetshenziswa nge-chipboard, ukuhlinzeka ngesisombululo esivikelekile nesinokwethenjelwa esivimbela ukuhlukanisa noma ukulimaza impahla.

I-5. Ukufakwa kalula: Idizayini yalezi zikulungisa ivumela ukufakwa okulula nokusebenzayo, ukunciphisa umzamo odingekayo ukuze uwavikele endaweni.

I-6. Ukusebenza Kwesikhathi Eside: Ngenxa yokumelana nokuqina kwabo kokugqwala nokuqina, izikulufu ezingenasisekelo ze-chipsoard Chipboard zinikeza ukusebenza kwesikhathi eside, zinciphisa isidingo sokulungiswa noma ukufaka esikhundleni.

7. Ukuguquguquka okuguquguqukayo

Izicelo zezikulufo ze-chipboard ezingenasici

●Ukukhiqiza ifenisha:Izikulufo zeChipboard zibalulekile ekuqopheni izinhlobo ezahlukahlukene zefenisha, kufaka amatafula, izihlalo, amakhabethe namathumbu. Amandla abo okujoyina ngokuphepha amaphaneli we-chipboard aqinisekisa ubuqotho besakhiwo sengcezu yefenisha.

●I-CACHRCK:Ekhishini nasekhishini amakhabethe, ama-chipboard screws adlala indima ebaluleke kakhulu ekuqopheni amabhokisi eKhabhinethi futhi anamathisele i-Hardware efana nama-hinges nama-slides amakhabethe.

●Ukufakwa Phansi:Ekufakweni kwama-laminate kanye nokufakwa kwe-fearting zokhuni, kusetshenziselwa izikulufo zeChipboard ukuvikela indawo yokuvimbela, ukudala isisekelo esizinzile sezendlalelo zokugcina.

●Amaphrojekthi we-DIY:Izikulufo zeChipboard zingukuqala kokukhetha kwabantu abathanda i-DIY abasebenza kumaphrojekthi ahilela i-chipboard noma i-parpleappleapp, njengokwakha amashalofu, amayunithi wokugcina noma ama-Workbenches.

●Izicelo zangaphandle:Ezinye izikulufo ze-chipboard ziphathwa ngezimbali ezivimbela ukubhuka ezibenza zilungele izinhlelo zokusebenza zangaphandle. Zingasetshenziselwa ukuhlanganisa ifenisha yangaphandle, izinhlaka zengadi, noma ama-deseste.

| Ububanzi bethreyimu yokuqala | 2,5 | 3 | I-3.5 | 4 | 4.5 | 5 | 6 | ||

| d | umnciphikazi | 2,5 | 3 | I-3.5 | 4 | 4.5 | 5 | 6 | |

| uku | 2.25 | 2.75 | 3.2 | I-3.7 | 4.2 | 4.7 | I-5.7 | ||

| P | Pitch (± 10%) | 1.1 | 1.35 | 1.6 | 1.8 | 2 | 2.2 | 2.6 | |

| a | umnciphikazi | 2.1 | 2.35 | 2.6 | 2.8 | 3 | 3.2 | 3.6 | |

| dk | max = usayizi ongokoqobo | 5 | 6 | 7 | 8 | 9 | 10 | 12 | |

| uku | 4.7 | I-5.7 | 6.64 | 7.64 | 8.64 | 9.64 | 11.57 | ||

| k | 1.4 | 1.8 | 2 | 2.35 | I-2.55 | I-2.85 | 3.35 | ||

| dp | max = usayizi ongokoqobo | 1.5 | 1.9 | 2.15 | 2,5 | I-2.7 | 3 | I-3.7 | |

| uku | 1.1 | 1.5 | I-1.67 | I-2.02 | 2.22 | I-2.52 | 3.22 | ||

| Socket No. | 1 | 1 | 2 | 2 | 2 | 2 | 3 | ||

| M | I-2.51 | 3 | 4 | 4.4 | 4.8 | 5.3 | 6.6 | ||