Imikhiqizo

18-8 / A2 amantongomane e-hex engagqwali

ukucacisa

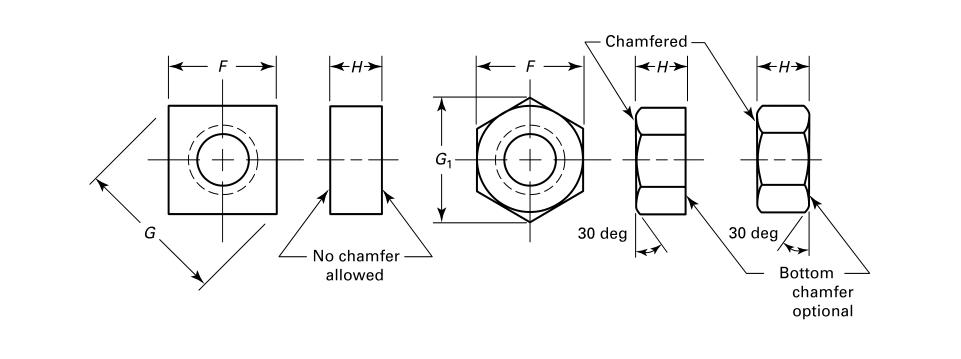

| Igama lomkhiqizo | Amantongomane e-hex engagqwali |

| Into uqobo lwayo | Kwenziwe ngensimbi engenacala 18-8, la mantongomane anokuphikiswa okuhle kwamakhemikhali futhi angaba yinkimbinkimbi kazibuthe. Baziwa nangensimbi engenacala. |

| Uhlobo lokwakheka | I-hex nati. |

| -Vamile | Amantongomane ahlangana ne-ASME B18.2.2 noma ukucaciswa kwe-DIN 934 ahambisana nalezi zindinganiso ezinobukhulu. |

| Okuzobisa uhlelo ngezinto | Lawa mantongomane alungele ukuqinisa imishini eminingi nemishini. |

isicelo

Amantongomane e-hex angenasici ane-fasteners enokwakheka okunamacala ayisithupha, aklanywe nge-hexagonal aklanywe ngama-bolts nezikulufo ukuvikela izingxenye ezimbili noma ngaphezulu ndawonye. Lawa mantongomane enziwe ngensimbi engenasici, enikeza ukumelana okuhle kakhulu, abenze balungele izinhlelo eziningi zezicelo, ikakhulukazi ezindaweni lapho kuchayeka khona umswakama, amakhemikhali, noma izinto ezinzima. Nazi ezinye izicelo ezivamile zamantongomane we-hex engenasici:

Imboni Yokwakha:

Amantongomane we-Hex asetshenziswa ekwakheni izinto ezisanhlathi eziphakemeyo, njengezinhlamvu, amakholomu, kanye nokuxhaswa, lapho ukumelana nokuqina kubalulekile.

Izithuthi:

Kusetshenziswe ekwenziweni kwezimoto kanye nokulungiswa kokuthola izakhi ezahlukahlukene, kufaka phakathi izingxenye zenjini, izinhlelo zokuphelelwa yizinhlelo, kanye nezinto ze-chassis.

Imishini kanye nemishini yokukhiqiza:

Kusetshenziswe emhlanganweni wemishini nemishini, enikeza ukuxhumana okuphephile phakathi kwezingxenye ezahlukene.

Electrical ne-elekthronikhi:

Kusetshenziswa amantongomane e-Hex emhlanganweni wamaphaneli kagesi, alawule amakhabethe, neminye imishini kagesi.

Izicelo zasolwandle:

Amantongomane e-hex angenasici anokulwa nokuphikiswa futhi athola ukusetshenziswa ekwakhiweni kwesikebhe nokulungiswa ezindaweni zasolwandle.

Amaphrojekthi wamandla avuselelekayo:

Kusetshenziswe ekwakhiweni kwama-turbines omoya, izakhiwo zephaneli yelanga, nezinye izingqalasizinda zamandla avuselelekayo.

| -Nemibukona Ubungako | Ububanzi obuyisisekelo bentambo yentambo | Ububanzi emafulethini, F | Ububanzi emakhoneni | Ubukhulu, h | Ukuthwala indawo yokugibela ku-HORRED AIS, FIM | ||||||

| Square, g | Hex, g1 | ||||||||||

| -Sisekelo | Imiz. | UMax. | Imiz. | UMax. | Imiz. | UMax. | Imiz. | UMax. | |||

| 0 | 0.060 | 5/32 | 0.150 | 0.156 | 0.206 | 0.221 | 0.171 | 0.180 | 0.043 | 0.050 | 0.005 |

| 1 | 0.073 | 5/32 | 0.150 | 0.156 | 0.206 | 0.221 | 0.171 | 0.180 | 0.043 | 0.050 | 0.005 |

| 2 | 0.086 | 3/16 | 0.180 | 0.1888 | 0.247 | 0.265 | 0.205 | 0.217 | 0.057 | 0.066 | 0.006 |

| 3 | 0.099 | 3/16 | 0.180 | 0.1888 | 0.247 | 0.265 | 0.205 | 0.217 | 0.057 | 0.066 | 0.006 |

| 4 | 0.112 | 1/4 | 0.241 | 0.250 | 0.331 | 0.354 | 0.275 | 0.289 | 0.087 | 0.098 | 0.009 |

| 5 | 0.125 | 5/16 | 0.302 | 0.312 | 0.415 | 0.442 | 0.344 | 0.361 | 0.102 | 0.114 | 0.011 |

| 6 | 0.138 | 5/16 | 0.302 | 0.312 | 0.415 | 0.442 | 0.344 | 0.361 | 0.102 | 0.114 | 0.011 |

| 8 | 0.164 | 11/32 | 0.332 | 0.344 | 0.456 | I-0.486 | 0.378 | 0.397 | 0.117 | 0.130 | 0.012 |

| 10 | 0.190 | 3/8 | 0.362 | 0.375 | 0.497 | 0.530 | 0.413 | 0.433 | 0.117 | 0.130 | 0.013 |

| 12 | 0.216 | 7/16 | 0.423 | 0.438 | 0.581 | 0.691 | I-0.482 | 0.505 | 0.148 | 0.161 | 0.015 |

| 1/4 | 0.250 | 7/16 | 0.423 | 0.438 | 0.581 | 0.691 | I-0.482 | 0.505 | 0.1788 | 0.193 | 0.015 |

| 5/16 | 0.312 | 9/16 | 0.545 | 0.562 | 0.748 | 0.795 | 0.621 | I-0.650 | 0.208 | 0.225 | 0.020 |

| 3/8 | 0.375 | 5/8 | 0.607 | 0.625 | 0.833 | 0.884 | 0.692 | 0.722 | 0.239 | 0.257 | 0.021 |